PRECISION MECHANICAL

PROCESSING

Steel, Stainless Steel, Inox Steel, Brass, Copper, Titanium and Aluminium alloys.

OMCB offers third party mechanical works for the firearms, hydraulic, pneumatic, electromedical, automotive, earthmoving, valves and petrochemical industries.

THIRD PARTY

MECHANICAL PROCESSING

With over 50 years of experience, we offer third party mechanical works for the firearms, plumbing, pneumatic, electromedical, automotive, earth-moving, valves and petrochemical industries, ensuring the highest quality standards and single components control during the whole production process.

QUALITY

We are a family business who believes in quality and constantly invest in human resources, in mechatronics and in technologies that allow our production to be more and more accurate.

Certified

processing

We’ve been a ISO 9001:2015 and ISO14001:2015 certified company that guarantees strict quality

standards and respect for the environment during each processing stage.

A dedicated

testing room

We test every product before, during and after the production to ensure an outcome that meets all the measurements and the characteristics requested by the drawings.

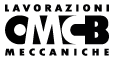

Flexibility and

production speed

Thanks to our new machinery, the entire factory automation and the mechatronics, we can guarantee a great production flexibility and faster delivery times.

Advanced

machine set

We constantly update our machine set to make our processes more precise, flexible and punctual, with mechatronics solutions and technologies.

Careful selection of

the raw materials

We carefully select the steel, the stainless steel, the inox steel, the brass, the copper, the titanium and the aluminium alloys to work with raw materials that respect the applications.

Processes include

treatments

Our collaboration with trusted and skilled workers, allows us to provide each component complete with thermal and surface treatments.

RAW MATERIALS STORING

We use control systems that analyze the surface and the chemical composition of the materials, to work with the exact material shown in the technical drawings.

CUT

During the mechanical processing, we use swiss-type lathes which can work with components that have a diameter ranging from 3mm to 32mm.

MATERIAL PROCESSING

Thanks to our bar NC lathes we execute third party mechanical processes on mechanical parts with a maximum diameter of 65mm.

THERMAL TREATMENT

We provide our clients mechanical components complete with thermal and surface treatments thanks to our collaboration with trusted treatmentists.

PACKAGING

Before being carefully packed, every component is controlled in a dedicated testing room that ensures the measures and the requested characteristics have been respected.

DELIVERY

Once the pieces are checked and approved for the delivery, we provide packaging and conservation solutions for an effective protection of the pieces against humidity and condensation during the shipping.

LATEST NEWS

Check out the latest news of the precision machining world.